Promotion Price 1500W 2000W 3000W 3 in 1 Handheld Fiber Laser Cutting Cleaning Welding Machine for Carbon Stainless Steel Aluminium Metal Iron Inox Soldering

Basic Info.

| Model NO. | KW-M |

| Technical Class | Continuous Wave Laser |

| Control | Manual |

| Power Density | Heat Conduct Welding |

| Laser Classification | Optical Fiber Laser |

| Type | Laser Mold Welding Machine |

| Color | Blue White / Red Black |

| Cleaning Width | 10~80mm |

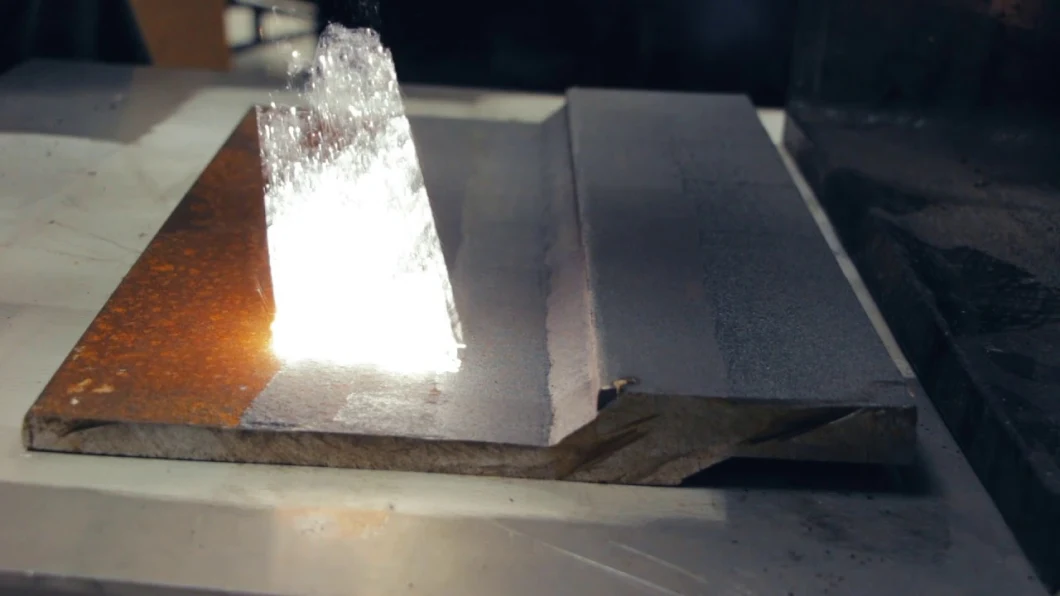

| Functions | Welding Cutting Cleaning |

| Laser Head | Relfar Qilin |

| Weight | 250kg |

| Protective Lens | D20*2 |

| Dimensions | 1400*700*1200mm |

| Water Chiller | S&a |

| Cooling Type | Water Cooling |

| Fiber Cable | 10m / 20m |

| Controller | Relfar Qilin |

| Auto Wire Feeder | Standard |

| Laser Source | Ipg Max Jpt Raycus |

| Laser Power | 1000W 1500W 2000W 3000W |

| Model | Kw-M |

| Transport Package | Wooden Box |

| Specification | 1400*700*1200mm |

| Trademark | KNOPPO |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 500 Sets/Month |

Packaging & Delivery

Package Size 120.00cm * 70.00cm * 110.00cm Package Gross Weight 200.000kgProduct Description

Product DescriptionAdvantages of Knoppo laser welding machine:- FAST SPEED : Compare with TIG welding , speed is 4X faster ;

- WELDING CAPACITY: Wide range of materials , 1000W 1500W 2000W And 3000W laser power can be option, max welding thickness is up to 8mm ;

- EASY OPERATION: Parameters is saved on system , reduce learning time.

- CONTINIOUS LASER SOURCE: High-quality and stable

- PRODUCTIVE: With laser cleaning and cutting functions , Pre- and post-weld cleaning capability

- WOBBLE WELDING: Adjustable 1~5mm welding width;

- SAFETY ALARM : High temperature alarm and low gas pressure alarm , protect laser source and laser head;

- SMALL HEAT AFFECTED ZONE

- 3 YEARS WARRANTY

Handheld fiber laser welding machine is widely used in the kitchen cabinets, staircase elevator, shelf, oven, stainless steel door, window guardrail, distribution box, medical equipment, communications equipment, battery manufacturing, craft gifts, household and other metal working industries. Pre- and post-weld cleaning capability

With hot temperature alarm and low gas pressure alarm , very sale . small and light , easy to operation.SUPER Control Sytsem

Different welding or cleaning parameters is saved on system , when you weld metal , you need only choose it . Also support multi languages , such as English , Polish , Spainish , Russian , Korean , Japanese , Portugal etc .

France Schineider Electric Parts

European CE standard , good quality and long lifetime . Automatic Wire Feeder

1. Touch Screen Display;

2. Adjustable wire feeding speed is 25~600cm/min;

How to change welding to cleaning ?

laser cleaning parts ( nozzle and lens ) will be sent with machine , you need only change welding nozzle and lens to cleaning nozzle and lens . then change welding mode to cleaning mode on system .

No. | Model | KW1000M | KW1500M | KW2000M |

I.Laser source | Raycus / MAX | Raycus / MAX | Raycus / MAX | |

1. | Output Power (w) | 1000w | 1500w | 2000w 3000w |

2. | Center wavelength | 1080nm ±5 | ||

3. | Fiber Cable length | 10m | ||

II.Water Cooling | 1.5P | 2P | 2.5P | |

III.Laser head ,standard model. Qilin /SUP/WSX (Optional) | ||||

1 | Spot size (mm) | 1.5/1.8/2.0 (XINGHONG) | ||

0.2-5mm adjustable (SUP / Qilin) | ||||

0-4mm adjustable (WSX) | ||||

2 | Working Mode | "O"(XINGHONG) | ||

dot/line/circle (SUP / Qilin) | ||||

"Z"(WSX) | ||||

3 | Protective lens | D20*2 | ||

4 | Auto Wire-feeder | Standard | ||

IV. Gas | N2/Ar | |||

V.Total Power Consumption | 7.5KW | 8.5KW | 10KW | |

VI.Voltage | 220±20% VAC 50/60Hz | 380±20% V AC 50/60Hz | ||

VII.Dimension (CM) | 62.5*174.6*109 | 62.5*175.6*124 | ||

Wooden box package , safedelivery

CertificationsOur fiber laser welding machine have CE certificates , all electric drawing and quality is suitable European standard .After Sales Service*3 years guarantee of the whole machine and we give lifetime maintenance free of charge. *Free training to make sure you master the operating of machine at our factory. * 24 hours online services through Whatsapp, Skype, Email or on the phone. *Engineers available for overseas training and after-sale services. * Friendly English version manual and operation video CD disk.Company Profile

Knoppo Automation is one of the world's leading manufacturers of high-tech industrial laser solutions, dedicated to providing laser intelligent equipment solutions and enabling our customers in various branches around the world to become more efficient and competitive. With more than 15,000 laser cutting systems in the market and a rapidly increasing global base, Knoppo Automation is in a favorable position to serve the international customer base, guaranteeing highest quality and shortest response times in already more than 100 countries. Our focus is on the innovation, continuous improvement and rapid development of technologies, all of which aim to increase efficiencies and flexibility, minimize costs while generating the highest levels of environmental friendliness and sustainability to our all benefit. We aim to provide key technologies and customized integration solutions for Industry 4.0 and smart factories, helping enterprises to make perfect use of the many opportunities arising in the digital age.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tube cutting systems, CO2 laser cutting engraving machine , laser welding machine etc . With our focused, highly skilled and experienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.